Modern technology for manufacturing lead-acid batteries with Ca/Ca plate alloying, which allows to create high-quality and dependable batteries with balanced characteristics.

Increased starting power for a successful start of the engine.

Dependable power supply of electronic comfort and safety systems. Excellent capacity performance from the increased number of plates.

High-tech design and grid alloy.

Maintenance-Free They do not require maintenance and watering.

Long service life. Increased plate strength and corrosion resistance.

Impact-resistant cases.

An innovative technology for the manufacture of lead-acid batteries, in which the electrolyte in the battery is not liquid, but is contained in an absorbed form in the microporous material of glass fiber separators, which results in a number of positive changes in the properties of the battery.

Advanced technology for manufacturing lead grids of positive current collectors for automotive starter batteries by stamping.

Increased strength and vibration resistance.

Extended battery life

Improved electrical conductivity: reduced internal resistance and improved adhesion with the active mass, which in the aggregate has a positive effect on electrical characteristics.

Environmental friendliness, significant reduction of emissions during the manufacture process

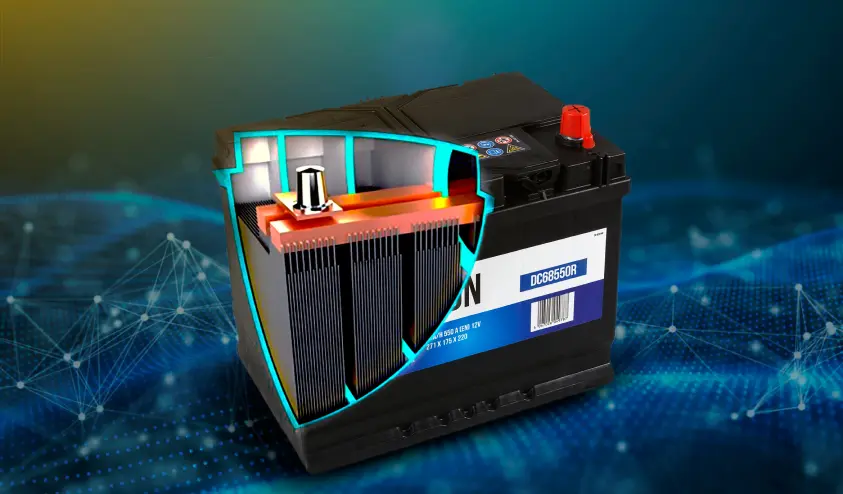

1

Lug

2

Positive plate grid

3

Positive plate

4

Positive plate with separator

5

Negative plate grid

6

Negative plate

7

Positive plate group

8

Busbar

9

Negative plate group

10

Negative plate group assembly

11

Central vent

12

Built-in folding handles

13

Terminal post